| Power: 380V 50HZ 3PH+N+E 4KW |

| Main control PLC: Mitsubishi |

| Main control touch screen: MCGS |

| Main control electric motor: 3.7kw |

| Feeder's electric motor: Step motor |

| Oil supply method: Automatic oil feeder |

| Production speed: Depending on skill level, 10-50pc/min, foot switch |

| Feeding length: 7-10mm |

| Material width: 100-455mm |

| Material thickness: 0.2mm |

| Mother roll ID: 152mm |

| Mother roll OD: 600mm |

| Material type: 5052H19 |

| Air supply: 0.5-0.8Mpa |

| Weight: 1.2ton |

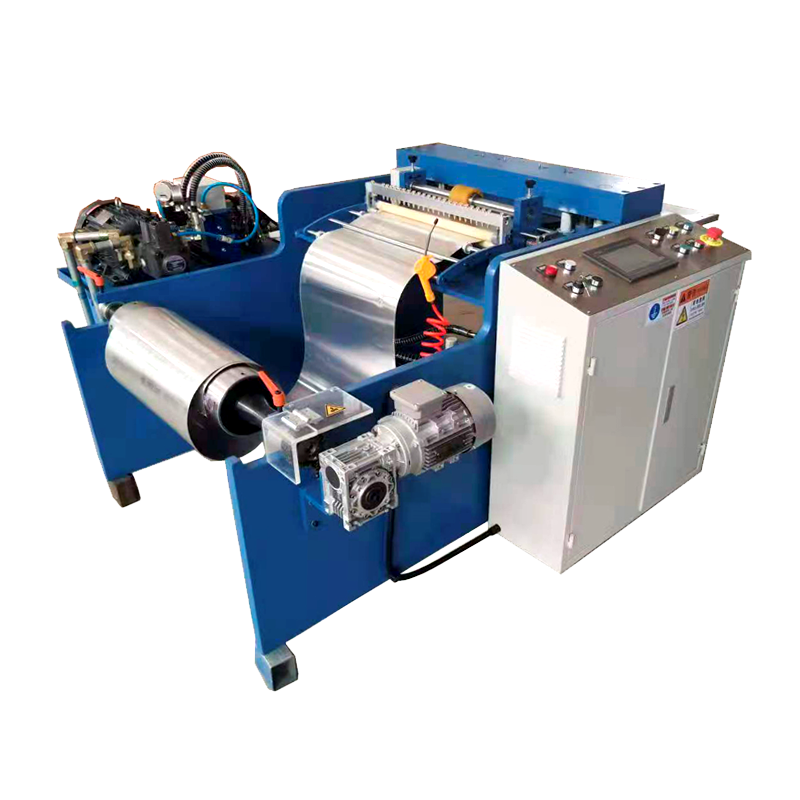

Product Description

Renderings show

What are the unique advantages of Semi Auto Metal Cutter Attaching Machine in metal processing?

In the field of metal processing, Semi Auto Metal Cutter Attaching Machine stands out among many processing equipment with its unique advantages. Although Ningbo Aikang Aluminum Foil Technology Co., Ltd is mainly committed to the design, development and production of environmentally friendly disposable aluminum foil products, the understanding of various advanced processing equipment helps us to continuously improve our production technology and efficiency.

1. Flexibility and controllability coexist

The semi-automatic metal cutting machine has higher flexibility in operation. Compared with fully automatic equipment, it allows operators to participate in the processing process to a certain extent, and can adjust the cutting parameters in time according to actual conditions. For example, for metal materials of different materials and thicknesses, operators can flexibly adjust parameters such as cutting speed and cutting angle according to experience and on-site needs to ensure the best cutting effect. This flexibility gives the semi-automatic metal cutting machine a greater advantage in handling complex or special metal processing tasks.

At the same time, the semi-automatic metal cutting machine also has a certain degree of controllability. It is usually equipped with an intuitive operating interface and control system, and the operator can easily monitor the various parameters in the cutting process and make precise adjustments. This controllability not only improves the precision and quality of processing, but also reduces the scrap rate caused by operational errors.

2. Obvious cost-effectiveness

In terms of cost, semi-automatic metal cutting machines are relatively economical. Compared with high-end fully automatic metal cutting machines, their prices are more affordable, and for some small and medium-sized metal processing companies, they are a very cost-effective choice. This enables companies to obtain efficient metal processing equipment and improve production capacity under a limited budget.

In addition, the maintenance cost of semi-automatic metal cutting machines is relatively low. Due to its relatively simple structure, maintenance and maintenance work is relatively easy. Operators can extend the service life of the equipment and reduce the maintenance cost of the equipment through simple daily maintenance, such as cleaning and lubrication.

3. Adapt to a variety of processing needs

Semi-automatic metal cutting machines can adapt to a variety of different metal processing needs. Whether it is the fine cutting of small metal parts or the rough processing of large metal sheets, it can perform well. For some irregularly shaped metal workpieces, operators can manually adjust the cutting position and angle to achieve precise cutting.

At the same time, semi-automatic metal cutting machines can also be used in conjunction with other processing equipment to form a more complete metal processing production line. For example, in conjunction with stamping equipment, welding equipment, etc., integrated processing of metal products can be achieved to improve production efficiency.

4. Easy operation and low training cost

The operation of the semi-automatic metal cutting machine is relatively simple, and the operator does not need to have too high a technical level. Generally speaking, after a short period of training, the operator can master the operation method of the equipment. For enterprises, this not only reduces the cost of human resources, but also enables rapid production and improves production efficiency.

In addition, the operation safety of the semi-automatic metal cutting machine is also relatively high. It is usually equipped with various safety protection devices, such as emergency stop buttons, protective covers, etc., which effectively ensure the personal safety of operators.

Semi Auto Metal Cutter Attaching Machine has unique advantages in metal processing, such as flexibility and controllability, obvious cost-effectiveness, adaptability to a variety of processing needs, easy operation and low training cost. Whether it is for large metal processing enterprises or small and medium-sized processing plants, semi-automatic metal cutting machines are an important equipment worth considering. It provides an efficient, economical and practical solution for the metal processing industry, and promotes the continuous development of metal processing technology.

English

English 日本語

日本語 عربى

عربى Español

Español